Importance of maching tolerances to high finish brake discs

Machining tolerances are the equivalent to the rules HENG TAIHUA abides by to ensure each brake disc is formed just right. Those rules dictate minimum and maximum dimensions all around the disc. If they don’t adhere to these rules carefully, the brake disc won’t fit as it should, or it won’t perform properly. This can make driving unsafe. So it’s really important to that you nail these down to keep everybody safe on the road.

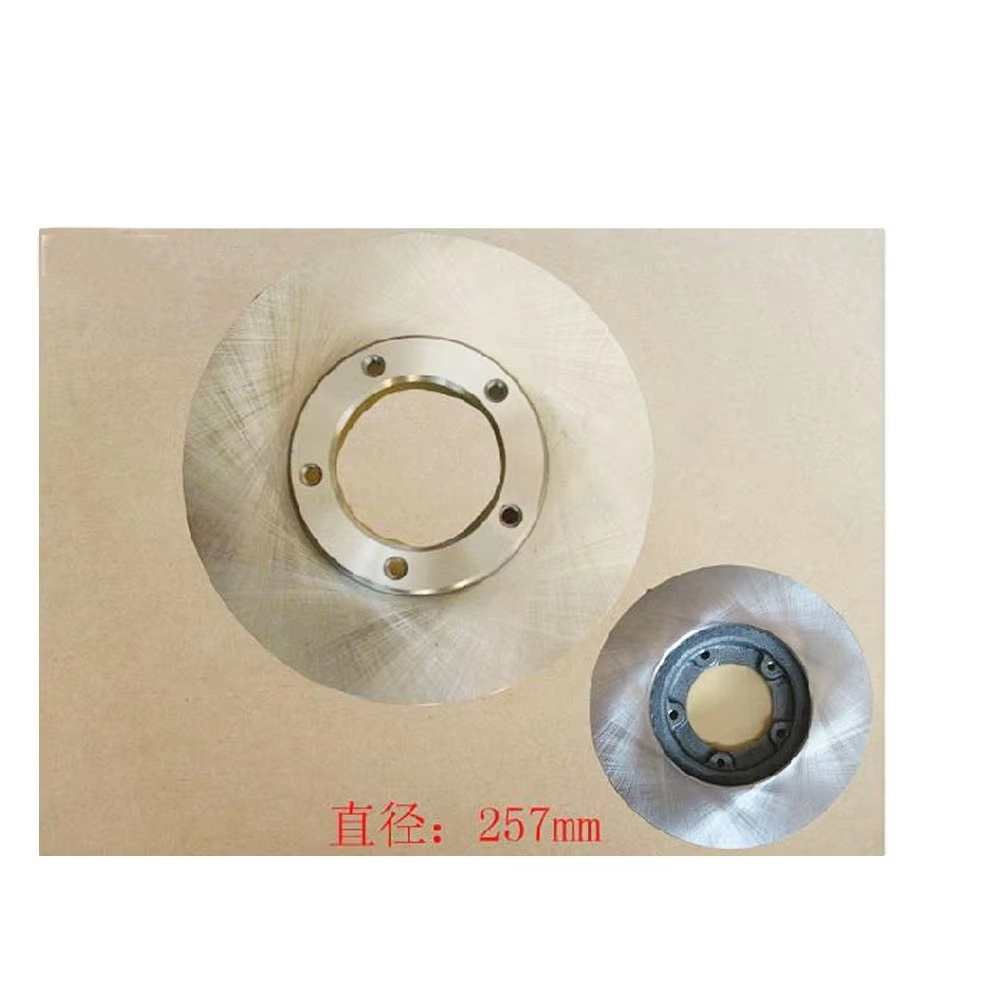

ENSURING PRECISE AND CONSISTENT BRAKE DISC MANUFACTURE THANKS TO NARROW MACHINING TOLERANCES

To ensure that each and every brake disc is impeccable, HENG TAIHUA keep the machining tolerances very tight. This is because they spend so much time ensuring that each part of the brake disc is the perfect size. In doing so, they ensure each brake disk looks the same and works the same, an absolutely critical need if your car’s brakes are to work correctly every time you use them.

The influence of tolerances and regenerative brake performance and safety

Machining tolerances aren’t all about looking good by essentially smoothing out the friction surface of the brake disc. They also see to it that brake disc works well and keeps ceramic disc brake you safe. If you get a brake disc made right, it'll stop your car smooth and quick. “It’s really, really crucial, particularly in emergencies. It’s because HENG TAIHUA are truly committed to it this.

The impact of machining tolerances on a brake disc and its performanceInSecondsHow does machining tolerances affect braking efficiency and brake disc wear Published in: 2018 13th World Congress on Aluminium8975004, 2018, pp

If the machining tolerances aren’t adhered to, it can really be a mess. For instance, if a brake disc is too thick or thin, it may not perform well, and it can wear out faster. This translates to potentially having ceramic disc brake pads to replace the brake discs twice as frequently, which can be an annoying and expensive inconvenience. That’s why nailing these tolerances is key to creating brake discs that last a long time and work effectively.

The difficulties and rewards of making ultra close machining tolerances on high-finish brake discs

It’s difficult to maintain such tight machining tolerances. It is a lot of work and it takes really good machines. But ceramic disc pad HENG TAIHUA believes it’s worth it. Apply some craft in shaping every brake disc and you get a product that both is reliable and safe. This is great news for drivers who rely on their brake discs, who can have peace of mind when they're out on the road knowing their brakes will work to the best of their ability every time.